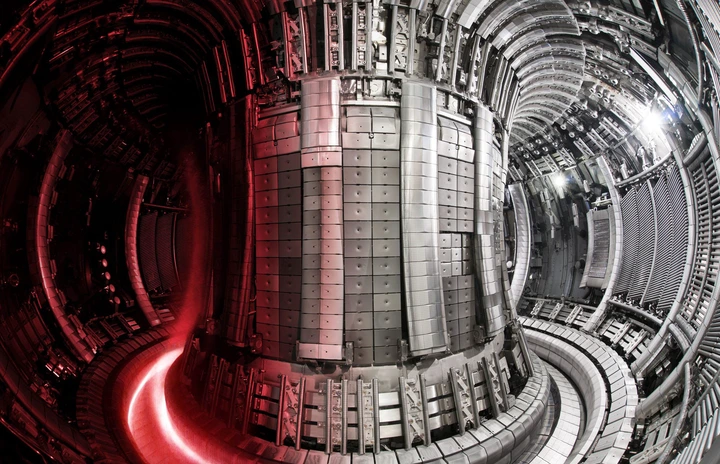

To create a miniature Sun on Earth, you'll require a significant amount of robust metal — and plenty of it.

View pictures in App save up to 80% data.

Scientists in the UK have forged 5.5 tonnes of a new kind of steel capable of withstanding the searing heat and intense neutron radiation of nuclear fusion, the same reaction that powers the Sun and stars. The breakthrough is another boost to Europe’s growing flock of fusion energy startups.

A working group known as NEURONE, part of the UK Atomic Energy Authority (UKAEA), has successfully developed reduced-activation ferritic-martensitic steel, commonly referred to as "RAFM." This achievement represents the first instance of RAFM being manufactured on an industrial scale within the UK.

“This is really positive and potentially has relevance for all fusionenergy projects,” Ryan Ramsey, COO at British startup First Light Fusion, told TNW.

Fusion reactors heat hydrogen atoms to very high temperatures, creating a charged state of matter known as plasma. By employing magnetic fields or lasers to compress this plasma, they induce the fusion of atoms, resulting in the release of vast amounts of energy that can be harnessed for electricity generation.

In a fusion energy reactor, the plasma can soar to astonishing temperatures of 150 million°C, momentarily turning these machines into the hottest locations in our solar system. To prevent the plasma from touching the metal walls, massive magnets are employed to keep it suspended in the air. The walls themselves are cooled to prevent them from becoming too hot, but standard steel simply cannot withstand the extreme conditions.

Ramsey stated, “The primary issue isn't the heat itself, but rather the damage caused by neutrons.” Neutron radiation can rapidly compromise the inner structures of a nuclear reactor.

"If you can't handle that, you'll find yourself frequently shutting down the fusion reactor to replace the walls, which results in a loss of power generation during those periods," he clarified.

View pictures in App save up to 80% data.

NEURONE has developed a new type of steel that can endure significant neutron exposure and temperatures reaching as high as 650°C, which could enhance the operational efficiency of upcoming fusion power plants.

For startups such as Oxford University spinout First Light, this development represents a significant advancement towards the ambitious objective of creating a commercially viable fusion reactor.

NEURONE utilized an electric arc furnace to forge the steel, relying on electricity rather than coal, located at the Materials Processing Institute (MPI) in Middlesbrough. According to UKAEA, this innovative forging technique could reduce the cost of producing RAFM by as much as 10 times compared to previous methods.

David Bowden, the leader of the NEURONE programme, stated, “Producing 5.5 tonnes of fusion-grade RAFM steel establishes a strong basis for the affordable manufacturing of this type of fusion steel in future commercial fusion initiatives.”

Despite huge progress, fusion energy has always seemed to be that “20-years-away” technology. But the tides might be changing. According to a poll at the International Atomic Energy Agency’s (IAEA) forum in London last year, 65% of industry insiders think fusion will generate electricity for the grid at a viable cost by 2035, and 90% by 2040.